Mining is one of the riskiest and most dangerous industries. Unmanned aerial vehicles (UAVs) are designed to help mitigate these risks and reduce the cost of mining operations. Their use allows for automating processes, improving data accuracy and personnel safety, and increasing the profitability of enterprises.

Traditional "ground-based" methods of surveying in quarries are associated with an increased level of danger, require more time, and are not always effective in complex and hard-to-reach areas. Here's how UAVs speed up and reduce the cost of mining operations and help control and audit the extracted and stored raw materials.

Surveying from the air: how UAVs are used for development and measurement in quarries

To ensure the safety and correctness of raw material extraction in mines and quarries, surveying is carried out. This is a set of field development activities that help determine the scope and timing of mining operations.

Traditionally, surveying works at open-pit mines are carried out using the instrumental method with a total station and GNSS receivers. The data on terrain changes are used to further create a digital terrain model.

UAVs have long proven to be an effective tool for solving many surveying tasks. Unlike ground-based surveying methods, drones increase the speed of data collection and allow obtaining reliable geometric data about the mining surface even in hard-to-reach areas. In addition, aerial photography can be carried out even during a work shift without interrupting operations at the site. This ensures prompt decision-making and increases profitability by reducing downtime of mining equipment.

A mandatory type of work in the mining industry is the regular calculation of the volume and weight of bulk raw materials and products (crushed stone, sand, etc.). This type of material is quite difficult to accurately account for, and standard surveying does not allow for accurate calculations by identifying characteristic points (top of the embankment, side, slope).

The method of determining the volume of embankments using UAVs involves building a digital model of all visible surfaces of the object as close to reality as possible - a point cloud, based on which all the necessary calculations are made.

The main advantages of this method are:

● high geometric accuracy of the models obtained;

● high speed and affordable cost of creating models based on point cloud data;

● simplification of data processing due to the possibility of their transformation;

● lower labor intensity and complete safety compared to surveying.

Calculating volumes and auditing raw materials using UAVs – safely, accurately, and efficiently

The use of drones in the mining industry can significantly improve the safety of company personnel and all those involved. Workers, surveyors, and geodesists do not need to visit such dangerous areas as slopes, cliffs, roads for the passage of equipment, etc. Full automation of the surveying process will allow personnel to obtain complete and comprehensive data without being exposed to danger.

The lower labor intensity and relatively low cost of surveying objects with drones allow you to fly over quickly and as often as necessary for the company. Thanks to up-to-date and regularly updated measurement data, the efficiency of resource management, determining the volume of excavation, etc. increases. The high quality and accuracy of the obtained geospatial data will allow creating and maintaining up-to-date mining and geographic information.

The creation of high-precision digital terrain models using UAVs will also allow us to analyze the condition of slopes and create terrain profiles to detect deformations and landslides in time based on a comparison of survey data. This will help to avoid landslides, properly draw up work plans, operate equipment efficiently, calculate dumps, and protect workers from injury.

UAVs can also be used for repeated surveys of quarries and mining sites. This will make it possible to study the number of raw materials extracted, determine the volume of earth embankments on the surface and the depth of crevices formed after the work, predict the amount of rock residue and check the stability of the surface at the site.

Using the latest software, processing of the data obtained with the UAV takes a few hours, which reduces the cost of routine operations for preparing reporting documentation related to monitoring the implementation of the state plan for stripping and mining operations and accounting for the movement of industrial reserves, losses, and depletion of mineral resources by several times. This also minimizes the human factor in data processing and enables the transition to paperless technology in spatial data processing and the generation of reporting and accounting documents.

Volume calculation and quantity determination – what other materials can be surveyed with a UAV

Provided that bulk raw materials and other products are fully visible from the air, UAVs can be used to determine the volume, weight, and quantity of the following materials:

● organic materials (e.g., wood and wood products)

● mineral raw materials (gravel, sand, pebbles, stones, gypsum, coal, sodium silicate, calcium, clay, etc.).

How Culver Aviation calculates the volume of bulk products

Culver Aviation provides services for calculating the volume of raw materials and hard rock using drones for its design and production.

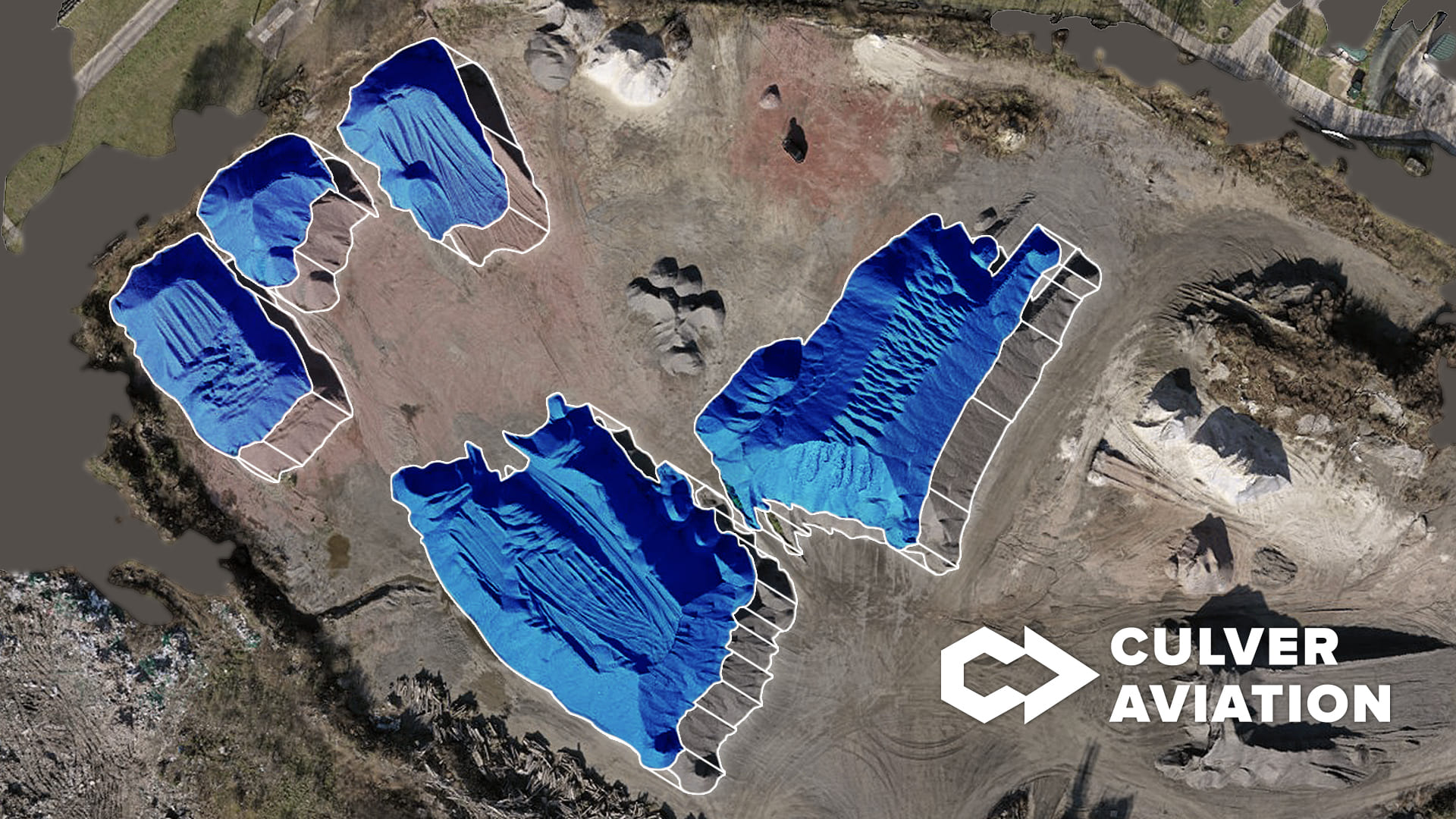

As part of one of the latest projects implemented in this area, Culver Aviation calculated the volume of stacks of crushed stone of various fractions on the territory of an existing asphalt plant. The company's specialists created an orthophotomap of the area and determined the 3D surface area and total volume of the embankments using aerial photography.

To confirm the data obtained, a control measurement of one of the stacks was carried out using an instrumental method using a total station and geodetic GNSS receivers. The difference in the data obtained using different measurement methods was about 1.8%, which suggests that both instruments are accurate.

However, the speed of obtaining information using the UAV was much higher: for example, it took Culver Aviation specialists less than an hour to fly over the entire territory of the asphalt plant with a copter, while it took about two hours to measure only one of the embankments using the ground method. Thus, we can talk about significant time savings, since it would have taken almost a whole day to measure all the stacks of crushed stone using the instrumental method.