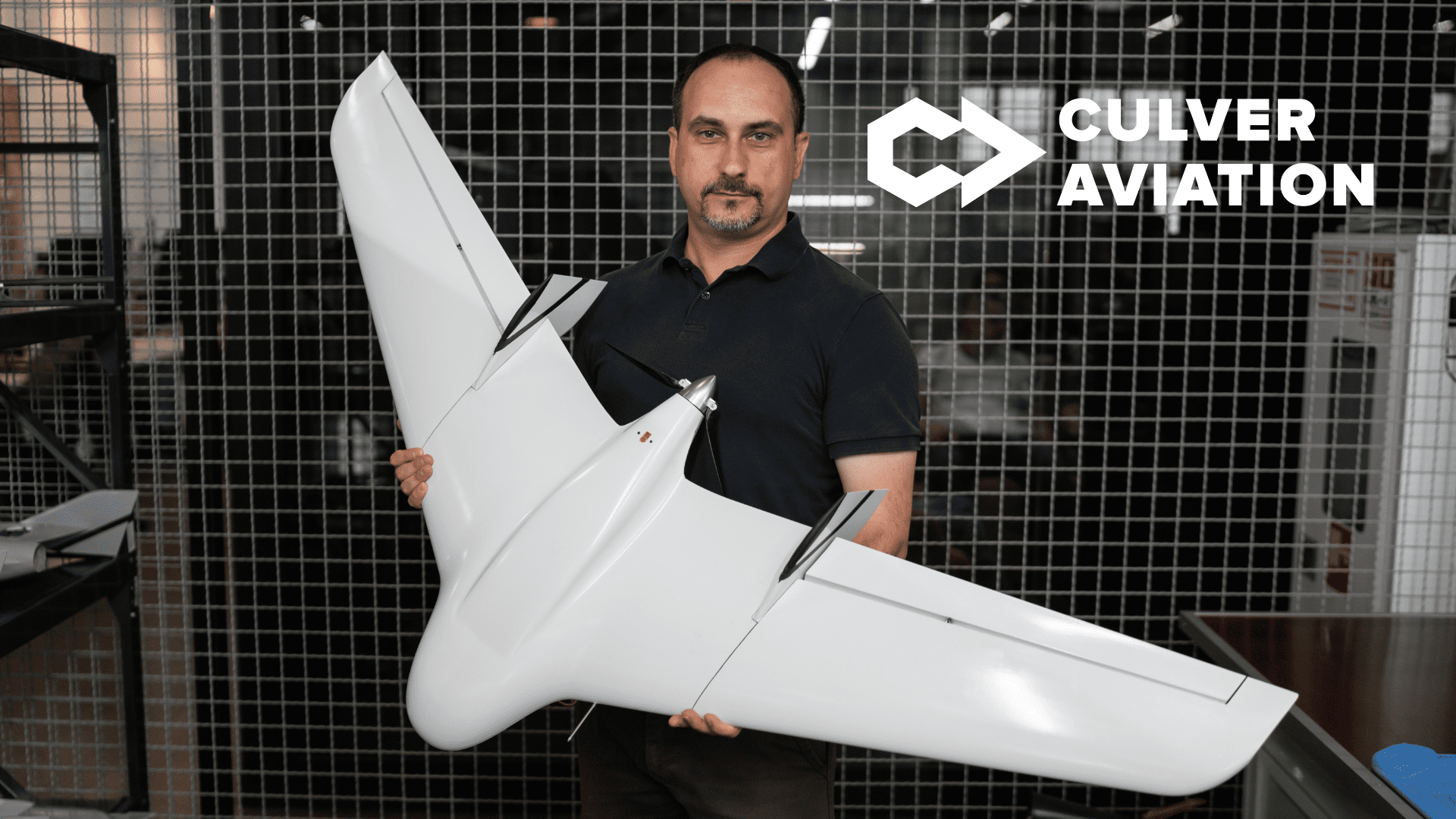

SKIF is a Ukrainian flying wing drone, developed by Culver Aviation specialists. Field measuring, crop surveillance, pipeline and highway monitoring is just a small list of tasks that SKIF successfully copes with.

To ensure the reliable operation of the drone Culver Aviation engineers made titanic efforts, and its creation was preceded by a large variety of tests. Read about which ones in our material.

The test of water resistance

Reliability is one of the main qualities of a drone, which must be equally effective in different weather conditions. For example, in case it suddenly rains during a mission.

During the development phase of the SKIF UAV, the hull was tested for moisture resistance in a special rain test chamber. The prototype aircraft was placed in a tank with a water supply that simulated real rain. The aircraft spent four hours in these conditions, which is conclusive proof that the moisture test passed.

Altitude test

When designing a UAV, the flight characteristics of the prototype are established using specialized software. To test the maximum flight altitude, the pre-production SKIF was flown to an altitude of 4,000 meters. It did well, but Culver Aviation engineers determined that the operating altitude range should not exceed 1,200 meters to obtain the best possible image quality.

Wind resistance test

For the correct and safe operation of the UAV, it is important to know under what conditions it will perform best, particularly under the influence of wind. Culver Aviation engineers tested the SKIF prototype in the open air with different air speeds to determine how the aircraft would behave in different wind loads.

The tests found that the aircraft could take off at wind speeds in excess of 20 m/s, but the limit was capped at 10 m/s to obtain clear images and extend the life of the vehicle.

Temperature tests

Knowing the environmental conditions at which the SKIF will perform without compromise and with the best end result is a prerequisite for getting started with the machine.

Conducting temperature tests showed that the limitation of flying the UAV is valid only in the range from -2 to +2°C, because under these conditions there is a high probability of icing of the aircraft hull.

The conclusion of the testers is that the SKIF can fly at any temperature except the 0°C limit.

Speed and flight time tests

Each aircraft has its own parameters and flight speeds. Culver Aviation engineers have conducted dozens of tests and determined that the minimum speed for the SKIF is 16 m/s, the maximum speed is 25 m/s, and the cruising speed, that is, the optimum speed is 20 m/s.

At this speed, the battery capacity is enough for 120-130 km, which is equivalent to 1.5-2 hours of flight.

Culver Aviation engineers also check how stable the UAV keeps its altitude. If during the flight a change in position of the aircraft is detected in the range of three meters, the aircraft is sent for revision. The accuracy of the route is also monitored.

Parachute system test

The SKIF does not have a landing gear system like larger aircraft. Like most wing-built aircraft, it uses a parachute to land. This also occurs during unpredictable situations, for example, if the SKIF is tipped over by a strong gust of wind.

The functionality of the parachute system in a critical situation is tested in the field. Two tests are done for this purpose: first - parachute release on operator's command, second - automatic triggering in case of excessive tilt level.

Note that such tests are conducted before each aircraft launch.

Camera tests

The main function of the drone is remote sensing of the ground surface and objects placed on it. The aircraft's "eye" must work like clockwork, so camera testing is a very important test.

SKIF uses a Sony A7R Mark IV with a 61-megapixel sensor and a fixed lens.

The quality of still images taken and data from the GNSS module is checked. If the photos and data are of the expected quality, the test is passed.

Tests of onboard electronics

The preflight preparation of the aircraft includes a test of the elevons (note: the control surfaces of the aircraft), as well as a check of the operability of all onboard electronics. At this stage, the greatest number of indicators are checked:

- engine operation;

- control systems of the UAV;

- air pressure receiver:

- stabilization system;

- stability of radio channel communication with the aircraft;

- navigation modules.

If at least one of the items is defective, the aircraft is sent for modification.

Tests Passed: SKIF in Service

Every completed SKIF has to complete three test flights without any failures before it enters service. Only then is it put into service. However, the work of the engineers does not end with the machine. Every 100 hours of flying time, the aircraft undergoes a complete inspection.

To make modern airplanes as safe as possible, they are tested comprehensively. Testing in aviation is the key to the reliability of any aircraft, even when it comes to unmanned aviation.